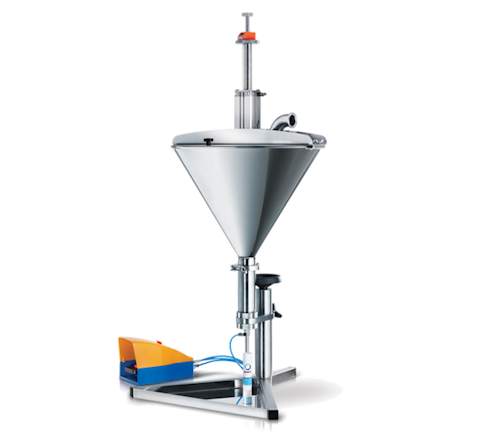

Pneumatic Piston Filler

The pneumatic piston filler can serve as a small batch bottle filling machine, tube filling machine, jar filling machine, or other open container filling machine. It works efficiently with dense fluids such as gels, creams, cosmetics, personal care, pharmaceutical, and CBD products.

Key features of the pneumatic piston filler:

- Constructed with high-quality stainless steel AISI 304

- All product-contact parts made of stainless steel AISI 316

- Suction at the filler nozzle

- Filling accuracy: < 1% of volume

- Wide range of dose volumes

- Output up to 900 pcs/hour

Main elements of the filling machine for creams, gels, and dense liquids:

- Fluid container (hopper) of 25 liters

- Pneumatic pedal

Level of automation:

The table-top filling machine is operated by one person. The operator inserts empty tubes or containers and releases the dosing using a foot pedal. Filled containers are manually removed after filling.

Possible applications:

Ideal for small to medium batch production or lab-scale operations. Perfect for creams, gels, and similar viscous products in cosmetics, pharmaceuticals, and food industries.