Helpful Articles

Recent advancements in 3D printed resin materials are opening the door to cheaper and more durable end use parts. For years, resins used in SLA printing were far too brittle to be functional in most industries. Newer resin materials offer heavily improved qualities such as rigidity, hardness, temperature resistance, and elasticity.

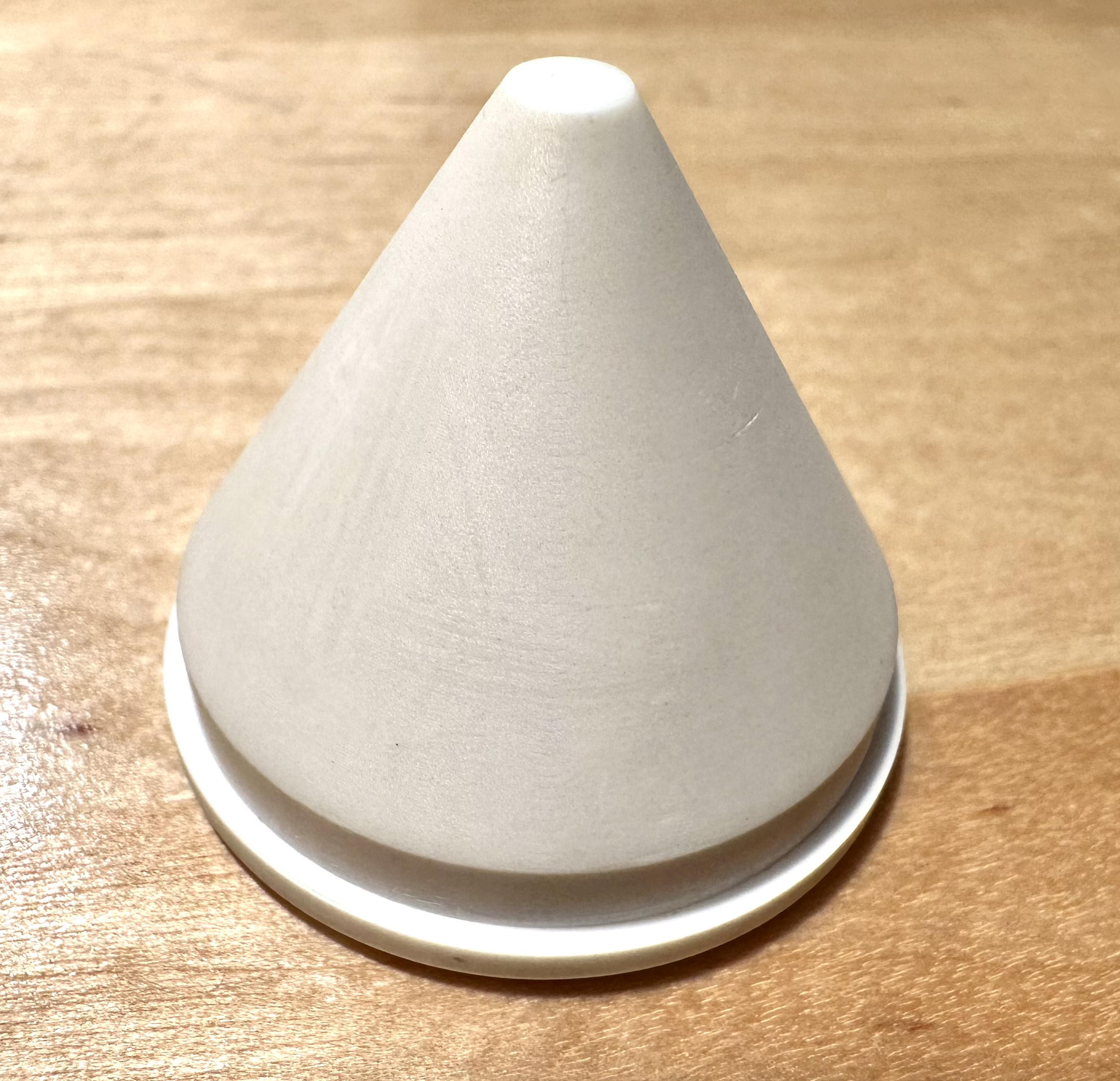

We are focusing on a ceramic-like resin that has ideal properties for use in automatic tube sealing machines. DLP technology also allows for extremely accurate and consistent part production. In the video below, you can see a demonstration of just how smooth and hard the surfaces are on this ceramic-like resin.

One challenge with automatic tube sealing machines is depressing tubes into the holders when the tubes are misshapen. Certain cone designs and materials can cause the tube wall to be rolled in on itself, which will then cause several problems with filling and sealing. Our resin cones are designed specifically to avoid this.

DLP printing allows for extremely smooth surfaces and layer heights of just 50 microns. The ceramic-like resin also helps smooth out layer lines, leaving a surface finish and tolerance close to high-end CNC machining. A smooth, low-friction surface as seen on our ceramic-like tube depressor and orientation cones helps eliminate the risk of tube walls rolling or crushing.

In addition to smooth surfaces, this ceramic-like resin has very high surface hardness. This means our tube depressor and orientation cones can resist scratches and indentations even after heavy use with aluminum tubes, which can be particularly difficult to work with. Read more on our aluminum tube tooling here.

The precision of DLP printing also allows threads and adapters for mounting to be printed directly in or on the model. Most FDM and even some forms of SLA printing would require the use of machined hardware due to a lack of dimensional accuracy, but DLP printers can consistently produce parts within a tolerance of +/-0.002”. Not only are the printed threads accurate, but they also have the strength for end-use.

Feel free to reach out and contact us with any questions.