Helpful Articles

How to Test Plastic and Laminate Squeeze Tube Seals

August 13, 2024

Tube seal testing is a crucial step in ensuring the quality and strength of your cosmetic tubes. Proper testing of tube seals significantly reduces the risk of product contamination, leakage, and degradation.

The two primary methods of tube seal testing are pressure testing and crush testing. Pressure testing is the most common method, with many tube sealing machines and tube fillers having built-in attachments to conduct these tests. When conducting a pressure test, compressed air is pumped into an empty sealed tube. The goal of this test is to first ensure no leaks appear at lower pressures for extended periods of time. Then, turn the pressure up to see if the tube seal or tube body fails first. The tube body will blow out on the side if your seals are appropriate quality. The video below demonstrates a simple pressure test.

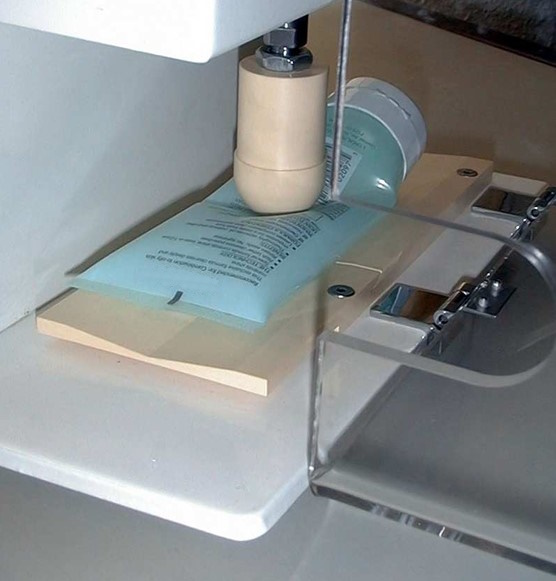

Crush testing is another common method for testing both empty and filled tubes. This method of seal testing utilizes a separate pneumatic device to smash sealed tubes with a piston, simulating many real-world conditions encountered during transport and use. High-quality tube seals should be able to withstand between 2–6 bars of crushing pressure without leaking any product.

Struggling to Achieve Strong Tube Seals?

Hot air tube sealing is the most effective and consistent way to seal plastic and laminate squeeze tubes. Compared to other sealing methods such as ultrasonic or hot jaw sealing, hot air technology provides a much cleaner, stronger tube seal. We provide custom CNC cut or 3D printed hot air nozzles for a wide variety of tube filling and sealing machines. Learn more about our CNC nozzles and 3DP nozzles here.

Feel free to reach out and contact us with any questions.